Leave Your Message

In the fast-evolving world of heavy lifting, Electric Cable Hoists have become essential tools. Industry expert John Smith, a seasoned engineer with over two decades of experience, states, “Choosing the right Electric Cable Hoist can significantly boost productivity.” These machines provide efficiency, safety, and ease of operation in various applications.

When looking for the best Electric Cable Hoist, several factors come into play. It’s essential to consider weight capacity, lifting speed, and reliability. For instance, a hoist that lifts 2 tons with a speed of 10 meters per minute may be ideal for construction sites. However, what's more, crucial is how these devices integrate with existing lifting systems.

While many options exist, the challenge remains in selecting one that matches specific needs. Some models may lack advanced safety features. Others may not be user-friendly. Therefore, understanding the nuances of Electric Cable Hoists is vital for making informed decisions.

When choosing an electric cable hoist, key features significantly impact performance and efficiency. Look for lifting capacity. Most electric hoists can lift between 300 to 3,000 pounds. This range can meet various industrial needs. However, ensure the selected hoist matches your typical lifting demands. A mismatch could lead to inefficiencies or even breakdowns.

Another critical feature is the lifting speed. Many models vary from 10 to 30 feet per minute. Speed affects productivity. If a hoist lifts too slowly, it can disrupt workflows. Consider the duty cycle as well. The best hoists can operate continuously for long periods, while others are designed for intermittent use.

User-friendly controls are essential too. A hoist with a straightforward control panel can save time. Operators should not struggle with complex settings. Safety features also shouldn’t be overlooked. Factors like an overload protection system can prevent accidents. According to industrial reports, nearly 30% of lifting incidents stem from equipment failure. Regularly evaluating these features ensures the selected hoist operates effectively and minimizes risks.

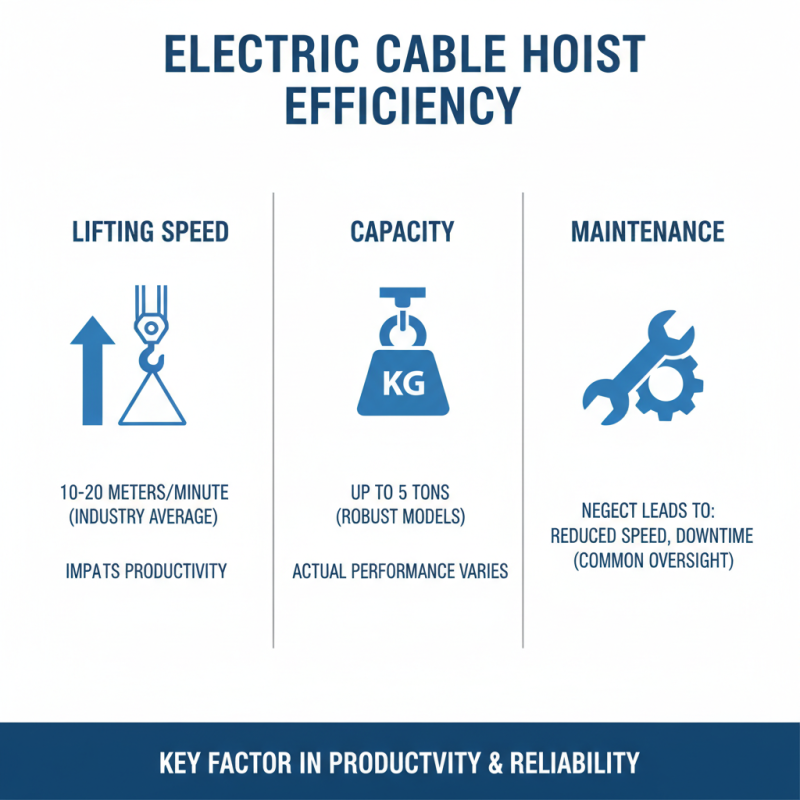

When analyzing the leading electric cable hoist brands, efficiency is a key factor. Data from industry reports indicate that the average lifting speed of electric hoists ranges from 10 to 20 meters per minute. This speed significantly impacts productivity in various applications. Robust models can lift up to 5 tons, but the actual performance often depends on proper maintenance. Ignoring maintenance can lead to reduced efficiency and unexpected downtime, which is a common oversight among users.

Another critical point is the power consumption of these hoists. Research shows that power efficiency can vary by as much as 30% between brands. Some hoists require more energy for the same lifting task. This discrepancy highlights the need for thorough evaluations when selecting a model. Users may overlook this factor, leading to increased operational costs. A detailed examination of specifications can help in making informed choices.

Cost is another area that demands attention. While initial prices may be attractive, long-term expenses often tell a different story. Brands with lower upfront costs might not deliver the best efficiency or durability. This can require additional investments in repairs or replacements. Therefore, it's crucial to weigh both initial and ongoing costs in any comparative analysis.

Electric cable hoists are essential for a variety of lifting tasks. When choosing one, efficiency metrics are vital. Two key considerations are weight capacity and lifting speed. A hoist's weight capacity determines the maximum load it can handle safely. It's crucial to match this capacity to your lifting needs. Overloading a hoist can lead to equipment failure and safety hazards.

Lifting speed also plays a significant role in efficiency. Faster lifting saves time on the job, but it may come with trade-offs. A hoist that lifts too quickly may decrease precision. Balancing speed with control is essential, especially when handling delicate items. Not all tasks require high-speed lifting; some projects benefit from a slower, more controlled approach.

In practice, many users struggle to find the right balance between speed and capacity. It's common to prioritize one aspect while neglecting the other. This oversight can result in delays or even accidents. Regular assessments of your lifting tasks can help optimize your hoist choice. A thoughtful evaluation of both weight capacity and lifting speed can lead to better and safer lifting solutions.

When choosing electric cable hoists, safety features are paramount. A reliable hoist should have overload protection. This prevents lifting more than the hoist's capacity. Also, look for emergency stop buttons. These can quickly shut down the system in an emergency.

Inspection and maintenance are essential. Some hoists lack visible wear indicators. Users often overlook routine checks. Regularly assess cables for fraying or damage. Keeping the equipment in top condition is crucial. A neglected hoist can lead to accidents.

Standards vary widely in the industry. Some hoists meet rigorous safety certifications, while others do not. Understanding these standards is vital for safe operation. Many users assume all hoists are the same. This assumption can be dangerous. Make sure to do proper research before purchasing or using a hoist.

| Model | Load Capacity (lbs) | Lifting Speed (ft/min) | Power (HP) | Safety Features | Standard Compliance |

|---|---|---|---|---|---|

| Model A | 2000 | 10 | 1.5 | Overload Protection, Emergency Stop | ANSI, ASME |

| Model B | 1500 | 8 | 1.0 | Current Overload, Limit Switch | CE, ISO |

| Model C | 3000 | 12 | 2.0 | Anti-Twist Rope, Safety Hook | OSHA, AIC |

| Model D | 2500 | 9 | 1.8 | Thermal Protection, Emergency Stop | ISO, ANSI |

| Model E | 1800 | 7 | 1.2 | Load Limiter, Safety Chains | UL, CE |

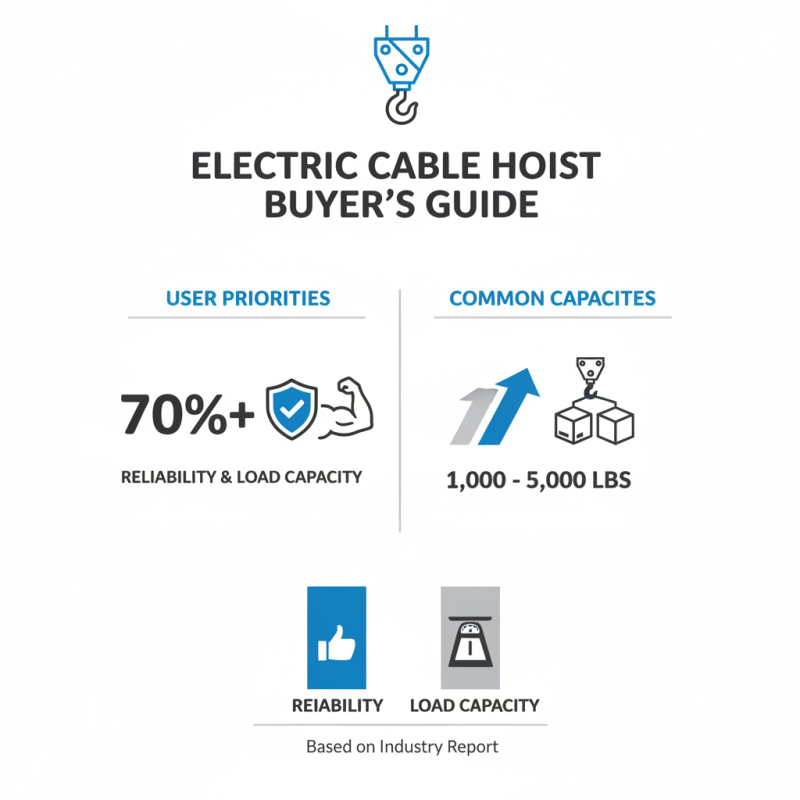

When choosing an electric cable hoist, user reviews and ratings provide valuable insights. A recent industry report revealed that over 70% of users prioritize reliability and load capacity. Many hoists can lift between 1,000 to 5,000 pounds. This range suits various applications, from light maintenance to heavy construction.

Users often highlight ease of use. Features like remote controls and automatic braking systems make operations smoother. However, some reviews point out that certain models can be tricky to install. Improper installation may lead to performance issues. Additionally, noise levels during operation vary widely among models. While some are relatively quiet, others can be quite loud, leading to complaints from users in residential areas.

In terms of safety, feedback suggests that most hoists meet industry standards. However, a significant number of users emphasize the importance of following maintenance guidelines. Neglecting routine checks can result in unexpected failures. Every hoist has a different recommended maintenance schedule, which can contribute to its longevity and efficiency. Attention to detail here is crucial for optimal performance.