Leave Your Message

In the dynamic world of supply chain management, optimizing warehousing and logistics elevators plays a crucial role. According to industry expert John Anderson, “The efficiency of your warehouses can hinge on the proper use of logistics elevators.” This statement underscores the importance of elevating not just goods but also overall operational effectiveness.

Warehousing and logistics elevators are essential tools in modern distribution centers. They facilitate the movement of products, reduce manual labor, and enhance safety. However, many companies still struggle with inefficiencies. Some elevators may not be appropriately sized for the load they handle. This miscalculation leads to bottlenecks and delays.

Optimizing these systems involves assessing current usage and identifying areas for improvement. Investing in smart technology can offer insights into performance metrics. Yet, it’s vital to remember that even the best systems may encounter challenges. Regular evaluations are necessary to ensure that these elevators meet evolving warehousing needs.

Elevators play a crucial role in optimizing warehousing and logistics operations. They facilitate the movement of goods between multiple levels of a warehouse, which can significantly improve efficiency. Heavy items can be transported without manual handling, reducing the risk of injuries. A well-placed elevator not only saves time but also maximizes storage space.

Tips: Consider the elevator’s weight capacity. Ensure it suits your warehouse's needs. Also, choose elevators with quick response times. This makes loading and unloading faster.

Integrating elevators into the warehouse layout is essential. Poorly planned placements can create bottlenecks. Think about waiting times and traffic flow. Regular maintenance is often overlooked but vital. Neglecting service can lead to unexpected downtime and frustration. It’s a reminder that efficiency sometimes requires constant evaluation.

Tips: Audit your elevator usage regularly. Analyze traffic patterns to optimize placements. Sometimes, less obvious areas need attention. Keeping a log of issues can guide improvements. A proactive approach is often necessary for long-term benefits.

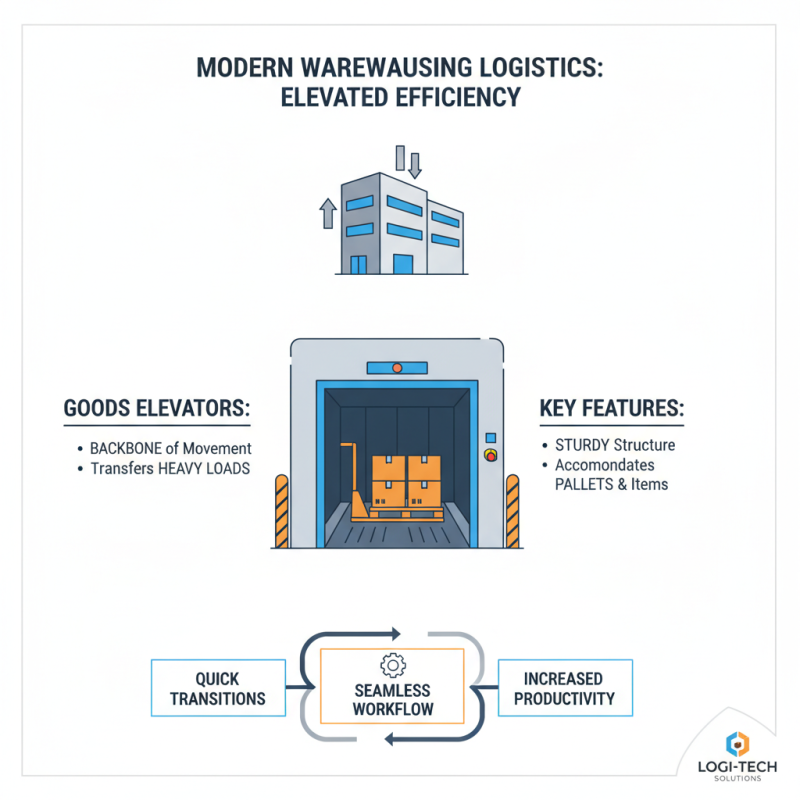

In modern warehousing, the efficiency of logistics elevates through specialized elevator types. Goods elevators serve as the backbone of movement, assisting in transferring heavy loads between floors. These elevators are designed with sturdy structures, accommodating both pallets and more delicate items. They ensure quick transitions, promoting a seamless workflow.

Another vital type is the freight elevator. Unlike standard models, these are built for heavier and bulkier loads. They have wider openings and reinforced platforms. Often, their capacity far exceeds typical passenger elevators. In busy environments, the efficiency of freight elevators can significantly influence overall operations.

While selecting elevator types, one must reflect on the layout of the facility. Are the elevators optimally placed for maximum access? Do they fit the specific needs of the inventory? Frequent issues arise when elevators are misjudged for the space. Misalignment leads to delays and frustration. Evaluating elevator performance becomes crucial for continuous improvement in logistics.

In designing warehouse elevators, several key factors can optimize efficiency. Space utilization is crucial. Elevators should be strategically placed to reduce travel time. A poorly located elevator can slow down operations. Integrating the elevator design with warehouse layout can enhance workflow significantly.

Load capacity is another important aspect. Many warehouses underestimate the weight and volume of goods. Choosing the right elevator that can handle maximum loads is vital. If an elevator frequently operates near its limit, it can lead to breakdowns. Regular maintenance checks must be scheduled to prevent long downtimes.

Elevator speed affects overall productivity. While fast elevators can seem beneficial, they may not always be. Balancing speed with safety is necessary. Employees must feel secure when using the elevator. A lack of proper safety features can lead to accidents. Always consider training staff on safe elevator use to improve overall efficiency.

Maintenance is crucial for logistics elevators in a warehousing environment. Regular inspections can prevent unexpected downtime. However, many facilities overlook this aspect until issues arise. Simple checks, like ensuring safety features work, are often neglected. Small problems can escalate quickly if not addressed.

Another common oversight is the maintenance schedule. Too many managers procrastinate on routine servicing. Creating a clear timeline can help. Log data on repairs and inspections makes this process easier. Not all staff are trained to notice warning signs. Frequent training sessions could bridge this gap.

Furthermore, documentation is often not thorough. Without precise records, analyzing trends can be challenging. In some cases, answers to recurring problems remain hidden due to poor tracking. Encourage teams to provide feedback and report anomalies. A culture of proactive engagement can enhance elevator uptime significantly.

In today's fast-paced warehousing operations, integrating smart technology into elevator systems can significantly enhance efficiency. Advanced sensors can optimize load management. These sensors can detect weight and adjust operations accordingly. This reduces downtime and improves safety. Automation plays a crucial role in this process, streamlining elevator controls.

However, challenges arise in implementing these technologies. Employees may not always adapt quickly. Training is often lacking, leading to errors. Integrating user-friendly interfaces is essential. A complex system can frustrate operators. Periodic software updates are necessary to keep systems running smoothly.

Furthermore, data collection can be a double-edged sword. While real-time analytics can optimize performance, they also require careful management. Misinterpretation of data can lead to poor decisions. Regular reviews are vital to avoid pitfalls. Elevators are not merely vertical transport methods; they are integral to effective logistics. Embracing smart technology requires continuous improvement and reflection on operational processes.

| Feature | Description | Benefits | Implementation Cost (USD) |

|---|---|---|---|

| Automated Control Systems | Systems that allow for automated scheduling and operation of elevators. | Increased efficiency and reduced waiting times. | $15,000 - $25,000 |

| Load Monitoring Sensors | Sensors that provide real-time data on load weights. | Enhances safety and prevents overload issues. | $5,000 - $10,000 |

| Predictive Maintenance | Technology that predicts maintenance needs through analytics. | Reduces downtime and prolongs elevator lifespan. | $10,000 - $20,000 |

| Mobile Application Integration | Apps that allow for remote operation and tracking of elevator status. | Convenience and improved workflow management. | $3,000 - $8,000 |

| Energy Efficiency Systems | Elevator systems designed to reduce energy consumption. | Lower operational costs and environmental impact. | $12,000 - $22,000 |