Leave Your Message

In the world of power generation, the efficiency and design of facilities are crucial. One significant advancement is the Thermal Power Chimneys Elevator. This innovative technology is pivotal for modern thermal power plants. According to Dr. James Reynolds, a leading expert in energy systems, “Thermal Power Chimneys Elevators enhance operational efficiency and safety.”

These elevators provide safe and efficient transport of personnel and materials to elevated sections of chimneys. Maintaining these tall structures can be daunting. The integration of elevators simplifies access, thus promoting better maintenance routines. A well-maintained chimney boosts the overall performance of the plant. These systems, however, also expose potential shortcomings. For instance, the initial installation costs and ongoing maintenance can be quite high.

Careful consideration is necessary when evaluating these systems. The benefits must outweigh their challenges. The importance of the Thermal Power Chimneys Elevator cannot be overstated; it plays a vital role in operational success. Understanding its advantages can lead to enhanced energy production and safety for workers.

Thermal power chimney elevators play a vital role in energy production. Their design prioritizes efficiency and safety. One of the key features is their ability to transport personnel and equipment to great heights, often surpassing 200 meters. This is particularly crucial for maintenance and inspections. A recent industry report indicates that effective maintenance procedures can reduce downtime by up to 30%.

These elevators are equipped with advanced safety systems. Emergency brakes, redundant power sources, and communication devices ensure safe operation. In a typical thermal power plant, unexpected shutdowns can cost over $1 million per hour. High-quality elevators can significantly mitigate such risks.

However, the installation and maintenance of these elevators present challenges. They require specialized skills and knowledge. Some facilities struggle to find qualified technicians. This issue can lead to delays in maintenance schedules. Additionally, the high cost of installation can deter smaller plants from adopting this technology.

Thermal power chimney elevators serve an essential role in maintenance. These systems provide access to high locations. Workers can safely reach the tops of chimneys without hazardous climbing. The design often includes safety rails and harnessing points, making the process more secure. Additionally, elevators reduce the physical strain on maintenance crews. Climbing ladders is tiring and can lead to injuries.

The efficient operation of chimney elevators allows for quicker inspections. Routine checks are vital to ensure structural integrity. Maintenance teams can identify issues faster when they reach heights easily. This timely response can prevent larger, costly repairs. However, not all facilities invest in these systems, and that’s an oversight. Downtime can increase without regular inspections. Ignoring this need can lead to safety risks.

There can be challenges too. Maintenance protocols must be updated and followed. Team training is crucial for effective use of chimney elevators. Some might find the transition from traditional methods difficult. Emphasizing safety and proper training can mitigate these issues. The upfront investment in these elevators may seem high but the long-term benefits are undeniable.

| Advantage | Description | Impact |

|---|---|---|

| Increased Safety | Reduces the risk of accidents during maintenance work at heights. | Enhances worker safety and compliance with safety regulations. |

| Time Efficiency | Speeds up access for maintenance tasks compared to traditional methods. | Reduces downtime of operations and costs associated with maintenance. |

| Improved Access | Allows easy access to elevated components of chimneys. | Facilitates thorough inspections and timely repairs. |

| Cost Savings | Lowers the overall maintenance costs through efficiency. | Long-term savings over reduced labor and operational downtime. |

| Enhanced Reliability | Regular maintenance leads to fewer unexpected failures. | Increases overall system reliability and efficiency. |

Thermal power chimney elevators are essential for efficiency and safety. Designing these elevators requires careful consideration of various safety factors. Height is a major concern. Elevators must function correctly in high, confined spaces. Malfunctions can be dangerous in emergencies. Ensuring reliable operation can be challenging.

Safety systems play a crucial role. Automatic brakes must activate instantly during power failures. Regular maintenance is critical to prevent failures. Inspections should be frequent to ensure all components work correctly. Compliance with standards is a must, yet sometimes overlooked.

Operator training is often underestimated. Staff should be well-versed in emergency protocols. Real life can be unpredictable; preparation is key. While designs may seem sufficient, real-world experiences can reveal flaws. An effective safety design constantly evolves based on actual usage and feedback.

When comparing thermal power chimney elevators to other systems, several unique advantages emerge. These elevators often boast efficient energy use. Their design allows for a straightforward vertical alignment. This translates to less downtime and lower maintenance needs. Unlike traditional elevators, thermal power chimney elevators can adapt to high temperatures, making them ideal for challenging industrial environments.

However, there are limitations. The installation of these elevators can be complex, requiring specific infrastructure. Not every building is suited for such systems. This can lead to potential operational issues. For some users, the benefits may not clearly outweigh these drawbacks. While they offer excellent performance, the initial investment is something to consider carefully.

In contrast, hydraulic or traction elevators may offer simpler installs. They are often more versatile for existing buildings. Yet, they might not handle extreme conditions as well. Thermal power chimney elevators could excel in industrial settings, but smaller operations may not require such capabilities.

Balancing performance and practicality is critical when choosing an elevator system.

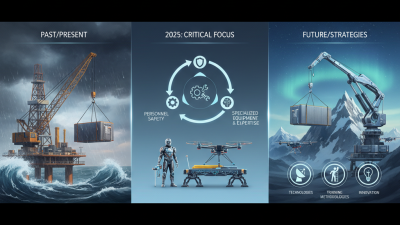

The future of thermal power chimney elevators looks promising. These elevators play a crucial role in maintaining efficiency. As technology advances, we expect improvements in energy consumption and safety features. Smart controls will likely become standard, allowing real-time monitoring.

New materials are being explored for better durability. Lightweight composites could reduce maintenance needs. Integrating sensors may improve operational reliability, but this also presents challenges. Data management requires attention. We must ensure that collected data is efficiently analyzed.

Regulatory changes might shape the future as well. Industries will need to adapt to new standards. The focus on sustainability cannot be ignored. Balancing efficiency and environmental impact is essential. Innovations are needed, but we must also consider the long-term implications of these developments.