Leave Your Message

The Electric Cable Hoist has become an essential tool in various industries. Its versatility and efficiency enhance productivity in construction, manufacturing, and warehousing. According to industry reports, the global market for electric hoists is expected to reach $2.5 billion by 2026. This growth highlights their increasing importance.

Selecting the right Electric Cable Hoist can be daunting. Many factors influence this decision, including weight capacity, lifting speed, and safety features. A recent survey indicated that 40% of users faced issues with their hoists due to improper selection. It's crucial to understand the project requirements to avoid costly mistakes.

Investing in an Electric Cable Hoist requires careful consideration. The wrong choice can lead to operational inefficiencies. Therefore, understanding the key factors that affect hoist performance is vital. Users must reflect on their specific needs before making a decision.

When selecting an electric cable hoist, understanding the various types is crucial. Electric cable hoists come in different configurations. Some are designed for light loads, while others handle heavy-duty tasks. Choosing the right type hinges on the weight requirements and the frequency of use. For instance, intermittent use may suit a lighter hoist. On the other hand, frequent heavy lifting demands a robust model.

Next, consider the power source options. Hoists can operate on AC or DC power. AC hoists are great for stationary applications. They are usually more powerful and suitable for industrial settings. In contrast, DC hoists are better for portability and often used in smaller projects. It’s also vital to assess the lifting height. Some tasks require a hoist that can reach extreme heights, while others do not. This factor can greatly influence your choice.

Watch out for noise levels, too. Some hoists may operate quietly, while others create significant noise. This could impact your working environment. Reflect on the safety features available as well. Some hoists come with overload protection, which is essential for safe operations. Not every hoist has the same safety measures, making it important to evaluate what is offered.

When selecting an electric cable hoist, consider key factors that impact performance. Load capacity is crucial. Most hoists can lift a range from 500 to 10,000 pounds. Knowing your needs helps prevent overload. An overloaded hoist may not only fail but can also lead to accidents.

Safety features cannot be overlooked. A high percentage of injuries stem from equipment failure. Look for hoists with limit switches and automatic shut-off features. A study published by the Occupational Safety and Health Administration (OSHA) reveals that the lack of safety measures leads to increased risks on job sites.

The environment plays a significant role in your choice. Indoor and outdoor hoists have different ratings for weather resistance. For instance, corrosion-resistant materials are essential for outdoor use. Ignoring environmental factors may shorten the hoist's lifespan significantly.

Ultimately, the decision should be a balance of these essential factors. Investing time in research will pay off. However, remember that even the best equipment may fail without proper maintenance. Regular checks and servicing are key to longevity.

When choosing an electric cable hoist, evaluating load capacity and safety ratings is essential.

Load capacity defines the maximum weight a hoist can lift. It's not just about the largest weight you need to lift. Consider future projects that may require more capacity.

This foresight can save you from upgrading your hoist soon after purchase.

Safety ratings are equally important. They indicate how well a hoist can handle loads under stress.

Look for certifications that validate safety features. Overloading can lead to accidents. Regular inspection and maintenance can help prevent failures.

Even the best hoists can have hidden flaws. Always prioritize safety; check the manufacturer’s guidelines.

Choosing the right hoist can feel overwhelming. Mistakes can happen, and not every situation is straightforward.

Some users might opt for a hoist that barely meets their needs. This can lead to complications later.

Take the time to evaluate your specific requirements. The details will guide your decision.

Safety and capacity should always go hand in hand.

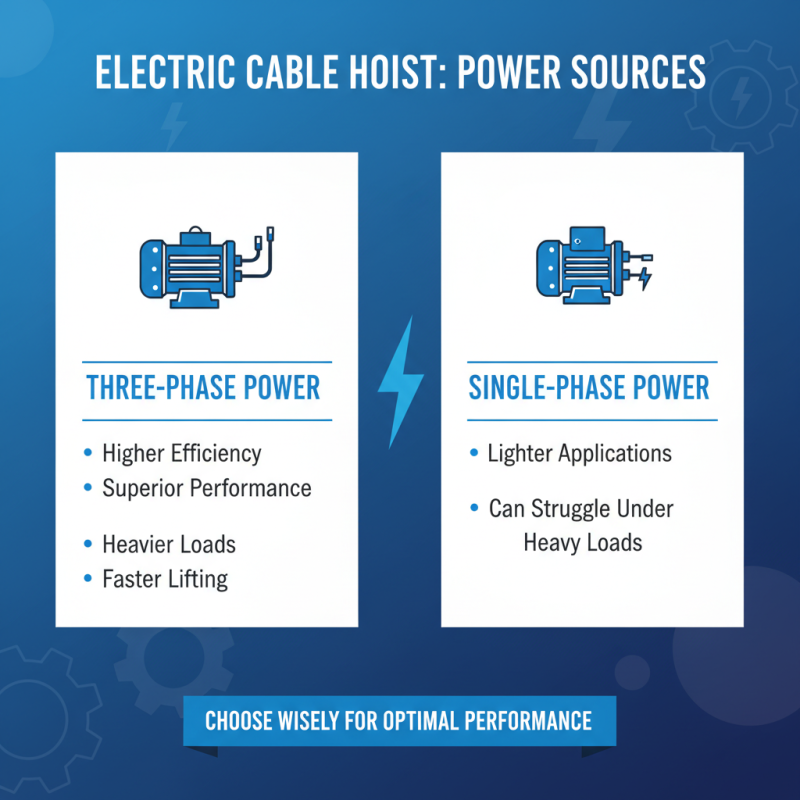

When selecting an electric cable hoist, considering the power source is crucial. Electric hoists commonly operate on three-phase or single-phase power. Industry reports indicate that three-phase systems provide higher efficiency and performance. They typically support heavier loads and ensure faster lifting speeds. Single-phase options might suffice for lighter applications, but they can struggle under heavy loads.

Tip 1: Assess your power availability. Make sure the installation site has the required voltage. You might be surprised by local supply limitations. Many overlook this basic check, causing delays and additional costs.

In addition to power types, evaluate the hoist's energy consumption. Modern electric hoists often feature energy-saving technologies. According to a recent study, these options can reduce energy costs by up to 30%. They may require a higher initial investment but yield savings over time.

Tip 2: Analyze your lifting needs. Choose a hoist that matches the power available. Underestimating needs can lead to inefficient operations. It's vital to balance power capacity with performance requirements.

Remember, a well-chosen power source optimizes hoist functionality. Many users regret not considering this earlier. Don't skip this step; it’s foundational to effective hoisting.

Maintaining electric cable hoists can be a daunting task. Regular inspections are crucial. Check for signs of wear and tear. Look closely at wires and hooks. Small frays can lead to major failures. Don't ignore strange noises during operation. They often indicate underlying issues that need attention.

Lubrication is another key aspect. Use appropriate lubricants on moving parts. This keeps everything smooth and reduces friction. However, too much grease can attract dust and debris. Finding the right balance can be tricky. Cleaning should also be part of your routine. Remove dust and dirt regularly. A clean hoist is a reliable hoist.

Pay attention to load limits. Overloading can cause premature wear. Even experienced operators sometimes push these limits. Keep a log of maintenance activities. Documenting helps in tracking performance over time. Remember, small mistakes can lead to costly repairs. Be proactive about maintenance, and your hoist will serve you better.

| Tip No. | Tip Description | Importance | Frequency of Maintenance |

|---|---|---|---|

| 1 | Check weight limits and ensure compatibility with your needs. | High | Before every use |

| 2 | Inspect cables for frays and wear. | High | Weekly |

| 3 | Ensure correct installation and operation settings. | Medium | Monthly |

| 4 | Lubricate moving parts regularly. | Medium | Quarterly |

| 5 | Keep hoist and cables clean from dirt and debris. | High | After heavy use |

| 6 | Test safety features like emergency stops and alarms. | High | Monthly |

| 7 | Review operating manual for specific maintenance instructions. | Medium | Annually |

| 8 | Check for electrical connections and signs of corrosion. | High | Monthly |

| 9 | Perform load tests to ensure proper functioning. | High | Quarterly |

| 10 | Schedule regular professional inspections. | High | Bi-Annually |